- TOP >

- COMPANY

GREETING

Conscientiousness and Responsibility as a Leading Maker

Nippon Keical is a top maker of calcium silicate thermal insulation material for industrial use.

Our products possess superior insulation and heat resistance capabilities, and we are constantly in pursuit of the development of products that maximize strength and lightness. Our products are widely used in industries such as the domestic and overseas petrochemical industry, thermal and nuclear power plants, and processed steel or municipal garbage incineration plants, and are valued for their contribution to energy conservation.

In recent years, industrial waste has become a major environmental issue. At our company, we were quick to introduce a recycling system for single-use waste calcium silicate thermal insulation material and create a manufacturing process to create our reclaimed insulation material, Recycal. We recycle thermal insulation waste material produced by existing plants.

We hope to make further contributions to environmental and energy conservation issues by being a conscientious and responsible leading maker of thermal insulation materials.

Our Business Concept

Continue to earn our customers' trust by producing a reliable supply of definitive quality calcium silicate thermal insulation, conscientiously and responsibly.

Company Profile

Name |

Nippon Keical Limited |

Founded |

February 1, 1979 |

Representative |

President & CEO Kenichi Fukui |

Location |

2020 Nakagawa Hosoe-cho, Hamana-ku Hamamatsu, Shizuoka 431-1304 Japan |

TEL |

+81-(0)53-522-1911 |

FAX |

+81-(0)53-523-1671 |

Capital |

¥300 million |

Shareholders |

Meisei Industrial Company Ltd. (https://www.meisei-kogyo.co.jp/) Nichias Corporation (https://www.nichias.co.jp/) |

Employees |

66 (as of June 27, 2024) |

About Our Services |

1) Production and Sales of Thermal Insulation Material 2) Industrial Waste Treatment Business 3) Businesses Related to The Above |

Products |

Keical Ace Super Silica, JIS #1-15 Calcium Silicate Thermal Insulation Material Keical Excel, Calcium Silicate Thermal Insulation Board for use in high temperatures |

Member of The Following Organizations |

Calcium Silicate Thermal Insulation Association Kanto-Koshinetsu Thermal Insulation Association |

Corporate History

February 1972 |

Production of our JIS #2-22 silicate thermal insulation material "Keical" begins at the Hamamatsu plant as thermal insulation manufacturer of Meisei Industrial Company Ltd. |

February 1979 |

Chemical manufacturer Mitsubishi Kasei (now Mitsubishi Chemical Corporation) and Meisei Industrial Company Ltd. establish Nippon Keical, a fifty-fifty joint venture with a capital of ¥100 million. Began factory remodeling for production of a JIS #1-13 extra light calcium silicate thermal insulation material "Keical Ace", based on Mitsubishi Chemical's production techniques. |

July 1979 |

Remodeling completed, all production changes over from "Keical" to "Keical Ace". |

September 1981 |

Keical Ace secondary production facility expansion begins. |

June 1982 |

Keical Ace secondary production facility expansion completed (capital investment of ¥300 million) |

August 1985 |

Received Japanese Industrial Standard (JIS A 9510) certification as a calcium silicate thermal insulation factory. |

September 1993 |

Recycling technology for single-use waste calcium silicate thermal insulation material is achieved (Patent #: 2993359). Began sales of thermal insulation material "Recycal", made from reclaimed industrial waste. |

October 1999 |

Company production and sales are restructured with the equity participation of Nichias Corporation, and the name of the product is changed to "Keical Ace Super Silica". |

October 2002 |

Company is restructured and becomes a joint venture with Meisei Industrial Company Ltd. and Nichias Corporation. |

November 2006 |

Receives ISO9001 certification. |

June 2008 |

JIS certification received after revision of industrial standard law. |

October 2009 |

Production of the "Recycal" has ended. |

March 2013 |

Production of the "Keical-2 Sillca light" has ended. |

April 2020 |

Started manufacturing and sales of [Mirror Ace]. |

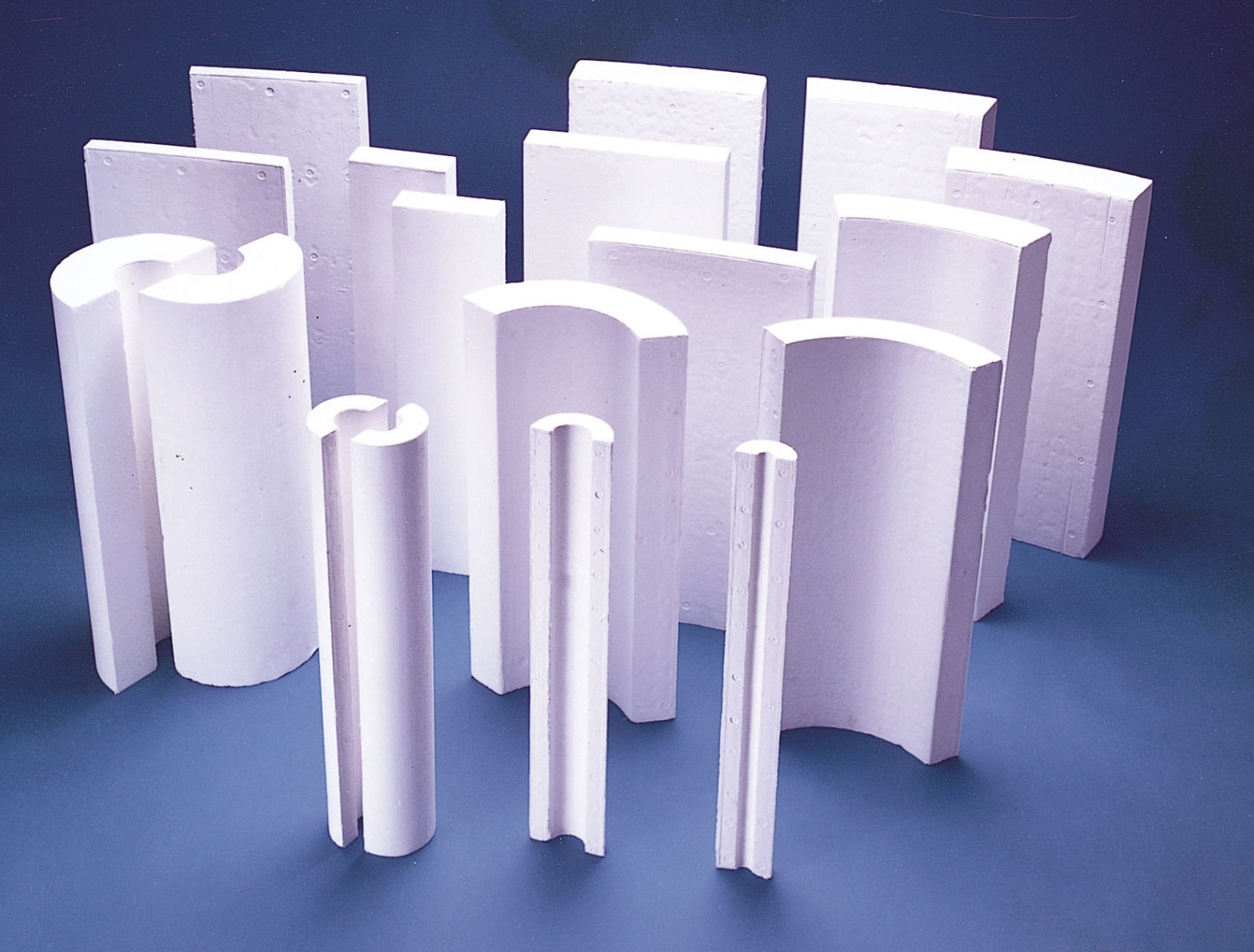

products line up

Keical Ace Super Silica

Keical Ace Super Silica is mainly composed of xonotlite crystal (6CaO·6SiO2·H2O) and its working temperature is 1000°C specified JIS No.1.

Not only the maximun working temperature is higher than that of JIS No.2, but also Keical Ace Super Silica shows no contraction in the mwdium temperature range (500°C or less), where the operation frequency is particularly large.

This ensures safe operation.

Keical Ace Super Silica WP

If the rain water splashes during construction work under the working conditions of 70°C to 150°C, like thermal insulation of the heavy oil tank, the water is difficult to vaporize and rust is produced, causing the thermal insulation performance to lower.

To prevent rain wqater during construction work, water-repelling material WP (Water Proof)-T (water-repelling of entire portion) is prepared.

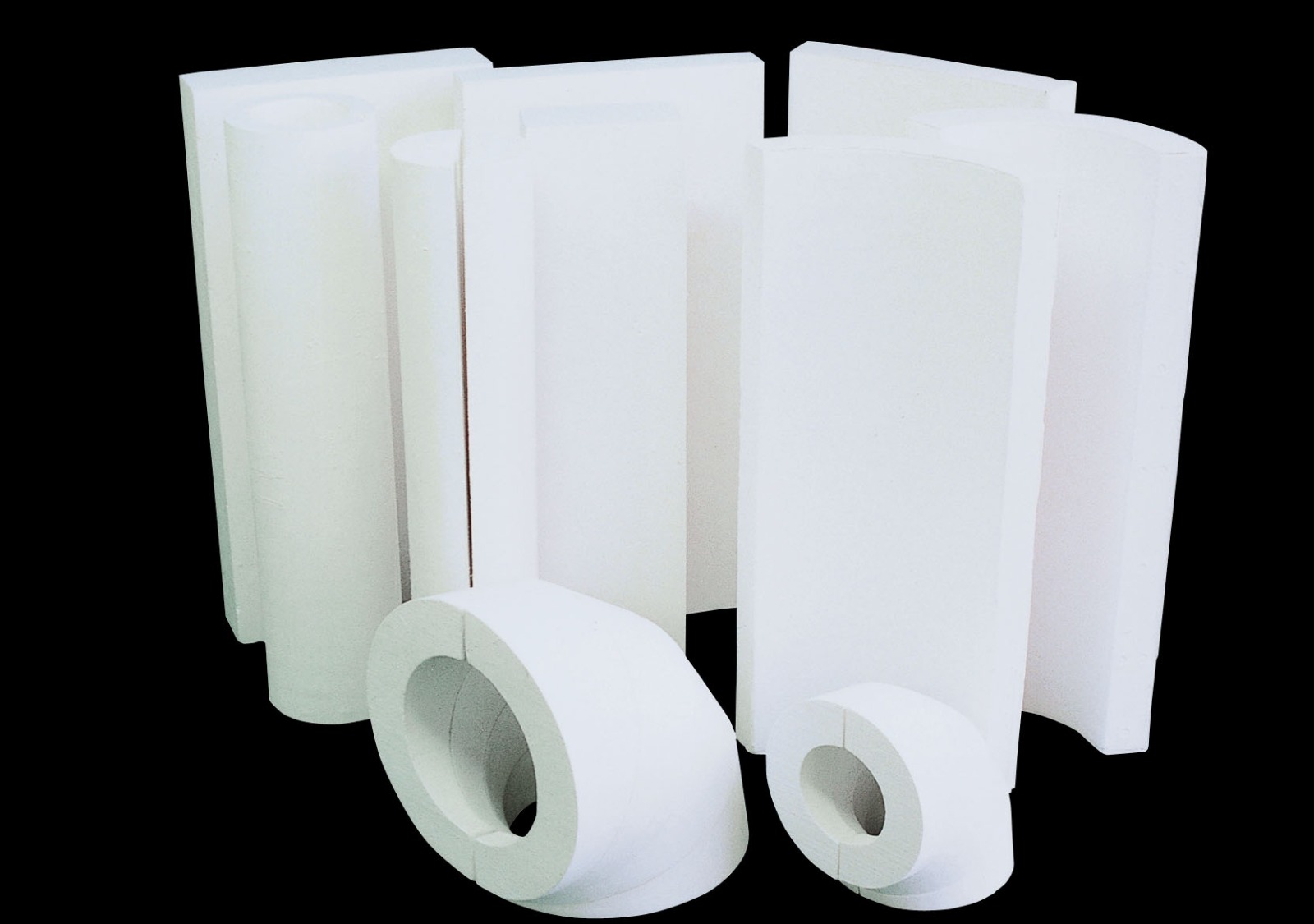

Elbow Ace

In the normal construction work of piping elbows, the thermal insulation tube is cut corresponding to the elbow parts and these cut tubes are jointed.

To shorten the construction work period and reduce the machining loss, Elbow Ace is available that the elbow parts are prefabricated.

When needing Elbow Ace, please contact us early.

Mirror Ace

This product is prefabricated according to the curved surface of the end plate of various pressure vessels.

Not only can the construction man-hour be greatly reduced, but also the gap is narrow and the use of jointing material is minimized, reducing industrial waste.

Keical Excel

Keical Excel uses the radiative heat shielding agent and is a product that suppresses the thermal conductivity, which increases like secondary curve as the temperature increases.

Additionally, the physical properties of Keical Excel are almost the same as those of the normal product.

Keical Excel is specially developed for high-temperature use.

Please use Keical Excel corresponding to your needs.